|

Product Details:

|

|

| Place of Origin: | China |

|---|---|

| Brand Name: | LKS |

| Certification: | CCS,DNV,BV |

| Model Number: | LKS-WRSS1185 |

|

Payment & Shipping Terms:

|

|

| Minimum Order Quantity: | 500sets |

| Price: | US$2.2-8.0 per set |

| Packaging Details: | Standard export carton |

| Delivery Time: | 10-15 days |

| Payment Terms: | L/C, T/T, MoneyGram, Western Union |

| Supply Ability: | 5000 sets per month |

|

Detail Information |

|||

| Type | Galvanized,Wire Rope Sling | Material | Steel,High Carbon Steel,PVC+Gal Wire,PVC Or PE Coated |

|---|---|---|---|

| Application | Industrial,facility,equipment,lifting | Standard | AISI,DIN,ASTM,BS,JIS |

| Steel Grade | Stainless Steel,High Carbon Steel | Alloy Or Not | Non-alloy |

| End Parts | Reinforced Loop,steelyard Hook | Service | ODM/OEM |

| High Light: |

Aircraft wire rope,Stainless Wire Rope |

||

Product Description

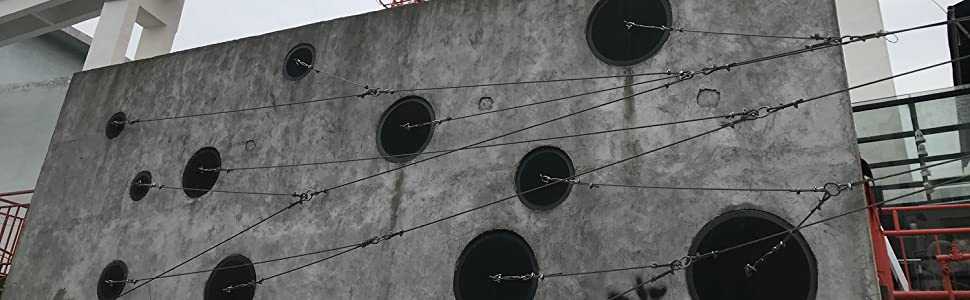

Stainless steel wire ropes boast higher corrosion resistance to salt water than galvanized wire ropes, so they are the best choice of marine applications. Meanwhile, the bright appearance of galvanized wire ropes will dull over time, but stainless steel wire rope will maintain its bright and modern appearance for years. Therefore they are generally used in decoration for modern display and architectural purposes, such as railings, architectural cables, cable balustrades, handrails, etc.

Stainless steel wire rope

Normally, stainless steel wire rope is made of 304, 305 or 316. And here is a simple comparison of these materials:

The 304 material, as the most common type, is magnetic with excellent corrosion resistance and strength compared with galvanized steel wire ropes. But it still will corrode to some extent over year so it is not suitable for marine and food applications.

The 305 material is more corrosive resistant than 304. Meanwhile, it is largely non-magnetic perfectly suited for aeronautical and naval fields.

The 316 materials is the most corrosive resistant type and highly used in high corrosion environments and places with high salt spray. But the 316 material is about 10% less strength than 304 stainless steel.

Construction:

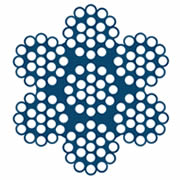

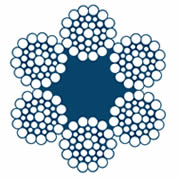

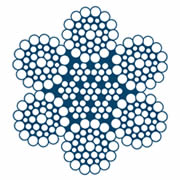

Four main constructions of stainless steel wire ropes - 1 × 19, 7 × 7, 7 × 19, 6 × 36 FC/IWRC are available as shown below:

1 × 19 stainless steel wire rope

Features:

Low stretch.

Excellent breaking load qualities.

High decorative appearance.

Application:

Marine industry such as rigging, sewage treatment work and mast stay.

Architectural applications including balustrades, guardrail and decking, etc.

| Type | Cable diameter | Tensile strength | Minimum breaking load | Weight |

|---|---|---|---|---|

| SSWR-119-1 | 0.54mm | 1570Mpa | 0.24KN | 0.001kg/m |

| SSWR-119-2 | 1mm | 1570Mpa | 0.82KN | 0.005kg/m |

| SSWR-119-3 | 1.2mm | 1570Mpa | 1.28KN | 0.007kg/m |

| SSWR-119-4 | 1.5mm | 1570Mpa | 1.86KN | 0.011kg/m |

| SSWR-119-5 | 1.8mm | 1570Mpa | 2.67KN | 0.016kg/m |

| SSWR-119-6 | 2mm | 1570Mpa | 3.30KN | 0.02kg/m |

| SSWR-119-7 | 2.5mm | 1570Mpa | 5.15KN | 0.031kg/m |

| SSWR-119-8 | 3mm | 1570Mpa | 7.42KN | 0.045kg/m |

| SSWR-119-9 | 4mm | 1570Mpa | 13.2KN | 0.08kg/m |

| SSWR-119-10 | 5mm | 1570Mpa | 20.59KN | 0.124kg/m |

| SSWR-119-11 | 6mm | 1570Mpa | 29.68KN | 0.178kg/m |

| SSWR-119-12 | 7mm | 1570Mpa | 40.4KN | 0.243kg/m |

| SSWR-119-13 | 8mm | 1570Mpa | 51.99KN | 0.317kg/m |

| SSWR-119-14 | 10mm | 1500Mpa | 82.4KN | 0.495kg/m |

| SSWR-119-15 | 12mm | 1450Mpa | 118.65KN | 0.713kg/m |

| SSWR-119-16 | 14mm | 1340Mpa | 161.50KN | 0.927kg/m |

| SSWR-119-17 | 16mm | 1340Mpa | 210.93KN | 1.27kg/m |

| SSWR-119-18 | 19mm | 1260Mpa | 297.45KN | 1.78kg/m |

7 × 7 stainless steel wire rope

Features:

More flexible than 1 × 19 stainless steel wire rope.

More rigid than 7 × 19 stainless steel wire rope.

Excellent breaking load qualities.

Available form 0.54mm to 12mm in diameter

Application:

Marine industry such as rigging, sewage treatment work, steering cable and mast stay.

General engineering applications such as control cable, davit ropes and slings

| Type | Cable diameter | Tensile strength | Minimum breaking load | Weight |

|---|---|---|---|---|

| SSWR-77-1 | 0.54mm | 1770Mpa | 0.18KN | 0.0012kg/m |

| SSWR-77-2 | 0.68mm | 1770Mpa | 0.29KN | 0.0018kg/m |

| SSWR-77-3 | 0.81mm | 1770Mpa | 0.41KN | 0.0026kg/m |

| SSWR-77-4 | 0.9mm | 1570Mpa | 0.49KN | 0.0032kg/m |

| SSWR-77-5 | 1mm | 1570Mpa | 0.56KN | 0.004kg/m |

| SSWR-77-6 | 1.25mm | 1570Mpa | 0.88KN | 0.005kg/m |

| SSWR-77-7 | 1.5mm | 1570Mpa | 1.27KN | 0.009kg/m |

| SSWR-77-8 | 1.8mm | 1570Mpa | 0.83KN | 0.013kg/m |

| SSWR-77-9 | 2mm | 1570Mpa | 2.25KN | 0.016kg/m |

| SSWR-77-10 | 2.5mm | 1570Mpa | 3.52KN | 0.025kg/m |

| SSWR-77-11 | 3mm | 1570Mpa | 5.07KN | 0.034kg/m |

| SSWR-77-12 | 4mm | 1570Mpa | 9.01KN | 0.063kg/m |

| SSWR-77-13 | 5mm | 1570Mpa | 14.08KN | 0.098kg/m |

| SSWR-77-14 | 6mm | 1570Mpa | 20.28KN | 0.142kg/m |

| SSWR-77-15 | 7mm | 1570Mpa | 27.6KN | 0.193kg/m |

| SSWR-77-16 | 8mm | 1570Mpa | 36.05KN | 0.253kg/m |

| SSWR-77-17 | 10mm | 1570Mpa | 56.3KN | 0.393kg/m |

| SSWR-77-18 | 12mm | 1570Mpa | 81.1KN | 0.566kg/m |

7 × 19 stainless steel wire rope

Features:

Extremely flexible.

Ideal for where flexible is particularly required.

Suitable for serving as control cables.

Available form 0.75mm to 16mm in diameter

Application:

Marine industry such as rigging, sewage treatment work, steering cable and mast stay.

Control cable, davit ropes, guardrail and wire rope slings.

| Type | Cable diameter | Tensile strength | Minimum breaking load | Weight |

|---|---|---|---|---|

| SSWR-719-1 | 0.75mm | 1570Mpa | 0.39KN | 0.0024kg/m |

| SSWR-719-2 | 1mm | 1570Mpa | 0.52KN | 0.0038kg/m |

| SSWR-719-3 | 1.5mm | 1570Mpa | 1.17KN | 0.0086kg/m |

| SSWR-719-4 | 2mm | 1570Mpa | 2.08KN | 0.015kg/m |

| SSWR-719-5 | 2.5mm | 1570Mpa | 3.26KN | 0.023kg/m |

| SSWR-719-6 | 3mm | 1570Mpa | 4.69KN | 0.035kg/m |

| SSWR-719-7 | 4mm | 1570Mpa | 8.34KN | 0.061kg/m |

| SSWR-719-8 | 5mm | 1570Mpa | 13KN | 0.096kg/m |

| SSWR-719-9 | 6mm | 1570Mpa | 18.76KN | 0.138kg/m |

| SSWR-719-10 | 7mm | 1570Mpa | 25.5KN | 0.187kg/m |

| SSWR-719-11 | 8mm | 1570Mpa | 33.3KN | 0.243kg/m |

| SSWR-719-12 | 10mm | 1570Mpa | 52.1KN | 0.381kg/m |

| SSWR-719-13 | 12mm | 1570Mpa | 75KN | 0.548kg/m |

| SSWR-719-14 | 14mm | 1570Mpa | 102KN | 0.764kg/m |

| SSWR-719-15 | 16mm | 1570Mpa | 133KN | 0.974kg/m |

6 × 36 FC / IWRC stainless steel wire rope

Features:

The most flexible type.

Equal lay construction.

Excellent breaking load and good fatigue life.

Available in FC and IWRC style.

Application:

Large diameter slings, luffing ropes, lifeboat falls, crane ropes, etc.

General engineering applications such as control cable and davit ropes.

| Type | Cable diameter | Tensile strength | Minimum breaking load | Weight |

|---|---|---|---|---|

| SSWR-636-1 | 8mm | 1570Mpa | 35.8KN | 0.28Kg/m |

| SSWR-636-2 | 9mm | 1570Mpa | 45.3KN | 0.35Kg/m |

| SSWR-636-3 | 10mm | 1570Mpa | 55.9KN | 0.43Kg/m |

| SSWR-636-4 | 11mm | 1570Mpa | 67.6KN | 0.539Kg/m |

| SSWR-636-5 | 12mm | 1570Mpa | 80.5KN | 0.619Kg/m |

| SSWR-636-6 | 14mm | 1570Mpa | 109.5KN | 0.843Kg/m |

| SSWR-636-7 | 16mm | 1570Mpa | 143.1KN | 1.1Kg/m |

| SSWR-636-8 | 18mm | 1570Mpa | 181KN | 1.39Kg/m |

| SSWR-636-9 | 20mm | 1570Mpa | 224KN | 1.72Kg/m |

| SSWR-636-10 | 22mm | 1570Mpa | 271KN | 2.16Kg/m |

| SSWR-636-11 | 24mm | 1570Mpa | 322KN | 2.48Kg/m |

| SSWR-636-12 | 25mm | 1570Mpa | 349KN | 2.69Kg/m |

| SSWR-636-13 | 28mm | 1570Mpa | 438KN | 3.37Kg/m |

| SSWR-636-14 | 30mm | 1570Mpa | 503KN | 3.87Kg/m |

| SSWR-636-15 | 32mm | 1570Mpa | 572KN | 4.41Kg/m |

304 Stainless Steel, Strong, Durable, Anti-oxidation, Corrosion resistant, Good flexibility, High and low-temperature resistance.Strong enough for durable working life, minimum breaking strength 6400 pounds.

|

|

|

|---|---|---|

DIYStainless steel 304 wire rope with 7x19 standard construction is commonly used for rigging, hoisting, push-pull, and guying applications. | Beautify the deck7 groups of 19 strands braided together to form the cable, which is flexible good type of cable for handling bends and corners on cable railings | Excellent performance7x19Construction made of 304 stainless steel 1/4 inch diameter is strong enough to support it for outdoor use, will not rust, within a reasonable strength range, it will not break. |

stainless steel cable is commonly used for build a pretty cable railing project, can also be used for outdoors, shopping malls, vehicles, boats, etc.

Enter Your Message